The "Sticker Shock" Conversation

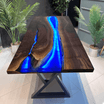

We have all been there. You are browsing online, and you see a listing for a "Walnut Style" table for $499. Then you come to CreateATable and see our Custom American Black Walnut pieces starting at $3,000+.

It is natural to ask: "What is the difference? It’s just wood and plastic, right?"

The truth is, the gap between "mass-market furniture" and "custom heirloom furniture" is massive. It’s the difference between a gold-plated ring that turns your finger green and a solid 24k gold band.

In this deep dive, we are pulling back the curtain on our manufacturing process to show you exactly where your money goes—from the rare forests of the American Midwest to the advanced chemistry lab that protects your table.

1. The Wood: American Black Walnut (Juglans Nigra)

Black Walnut isn't just "wood." In the world of fine woodworking, it is royalty. Native to Eastern North America, it is prized for a specific combination of traits that make it uniquely perfect for epoxy tables.

A Color Palette You Can't Fake Most cheap furniture is made of rubberwood or pine and then stained to look dark. But stain is superficial—if you scratch it, you see white wood underneath. Real American Black Walnut is naturally dark. Its heartwood ranges from rich chocolate and mocha to subtle purples and greys.

l The Live Edge Magic: The outer rings of the tree (the sapwood) are a creamy vanilla color. When we use a "Live Edge" slab, you get this stunning natural contrast—a dark core wrapped in a light halo. No factory in the world can replicate that organic transition. It is nature's fingerprint.

l Stability is King Wood is a living material; it breathes. It expands in summer humidity and shrinks in winter dryness. If a wood moves too much, it will literally rip itself away from the epoxy resin, causing catastrophic cracks. Black Walnut is famous for its Dimensional Stability. It is one of the most stable domestic hardwoods, meaning it plays very nicely with epoxy. It holds its shape, ensuring your table stays flat and crack-free for decades.

The "Salvaged" Story (Sustainability) At CreateATable, we practice Ethical Sourcing. A huge portion of premium walnut slabs come from "Urban Logging" or "Salvaged" trees. These are trees that were removed because they were dying, storm-damaged, or in the way of city planning—not trees cut down from virgin forests just for furniture. By buying a Walnut table, you are essentially sequestering carbon in your home and giving a fallen giant a second life .

2. The Chemistry: Bio-Based Resins

Not all epoxy is created equal. The cheap tables you see on budget sites often use industrial-grade resins that are high in VOCs (Volatile Organic Compounds) and prone to yellowing.

At CreateATable, we are pioneering the use of Bio-Based Epoxy Resins.

What does "Bio-Based" mean? Traditional epoxy is 100% petroleum-based. Bio-based resins replace a portion of that petroleum with plant-derived carbon, such as soybeans, cashew nut shell liquid (CNSL), or algae.

l Why it matters to you:

(1) Safety: These resins have significantly lower odor and off-gassing, making them safer for your home air quality.

(2) Clarity: Modern bio-resins have advanced UV inhibitors that prevent the "ambering" (yellowing) effect that plagues cheap epoxy. Your crystal-clear river will stay clear.

(3) Hardness: We use different formulas for different layers. A flexible resin for the deep pour (to absorb wood movement) and a harder resin for the topcoat (to resist scratches).

3. The Shield: Nano-Ceramic Technology

The number one fear of every epoxy table owner is scratches. "Will my keys scratch it?" "Can I put a hot coffee mug on it?"

To solve this, CreateATable offers an advanced Nano-Ceramic Coating upgrade. This is the same technology used to protect luxury cars, adapted for furniture .

How it Works: The ceramic coating contains microscopic silica (SiO2) particles that bond chemically to the resin surface.

1. Hardness Boost: It increases the surface hardness, making it significantly more resistant to swirl marks and micro-marring from cleaning cloths.

2. Hydrophobic Effect: This is the "party trick." Pour water or red wine on the table, and it will bead up into perfect spheres and roll off. Liquids cannot penetrate the pores of the wood or resin, making the table virtually stain-proof.

3. UV Sunscreen: The coating acts as an additional UV barrier, protecting the walnut color from fading and the resin from discoloring near windows.

4. The Human Element: 100+ Hours of Labor

The final factor in the price is time. A mass-produced table is stamped out by a machine in minutes. A CreateATable custom piece takes weeks.

l Kiln Drying: Slabs must be dried for months to reach the perfect moisture content (below 10%).

l The Pour: We pour resin in thin layers to prevent overheating (exothermic reaction), which can take days.

l Surfacing: The table is flattened on a massive CNC router.

l Sanding: This is the grueling part. Our artisans hand-sand every inch, stepping through grit levels from 80 up to 3000 grit to achieve perfect clarity.

l Finishing: Multiple coats of oil and ceramic are applied and buffed by hand.

When you buy from us, you aren't just paying for wood; you are paying for the 100 hours of skilled American craftsmanship that went into making that wood sing.

Conclusion: Value vs. Cost

A cheap table is a disposable expense. You buy it, it scratches, it wobbles, and you throw it out in 5 years. A CreateATable American Black Walnut table is an asset. It is a piece of functional art that holds its value and tells a story. It is the table your family will gather around for the next 30 years.

Ready to invest in the best? Browse our collection of (https://createatable.com/collections/epoxy-coffee-table) and find the one that speaks to you.

Frequently Asked Questions (FAQ)

Q: Is Black Walnut too soft for a dining table? A: No. Black Walnut has a Janka Hardness rating of 1,010 lbf. While it is softer than Oak or Maple, it is plenty hard for a dining table. It is actually preferred because it is less brittle and easier to repair if it does get dented.

Q: Does the bio-based resin smell? A: No. Once fully cured, our bio-based resins are inert, non-toxic, and food-safe. You can eat right off the table.

Q: Can I place hot pans on the table? A: We recommend using trivets. While the resin is heat resistant up to ~140°F, placing a boiling pot (212°F) directly on the surface can cause "heat rings." The ceramic coating helps, but it’s always best to protect your investment.